Inside the Smart Factory Revolution:

The world of manufacturing is undergoing a quiet but dramatic transformation. Once defined by assembly lines and repetitive tasks, modern factories are now becoming hubs of intelligence, connectivity, and automation. Welcome to the era of smart factories, where Industry 4.0 is redefining how goods are produced, monitored, and delivered.

The shift isn’t just about machines; it’s about creating an ecosystem where data, automation, and human expertise work together seamlessly.

What Is Industry 4.0?

Industry 4.0, often called the fourth industrial revolution, marks a departure from traditional manufacturing practices. It leverages cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and advanced data analytics to make factories smarter, faster, and more efficient.

In practical terms, this means production lines can self-monitor, identify inefficiencies in real time, and even predict maintenance needs before equipment fails. Machines and humans collaborate more closely than ever, with data driving nearly every decision on the shop floor.

The Role of Smart Factories

-

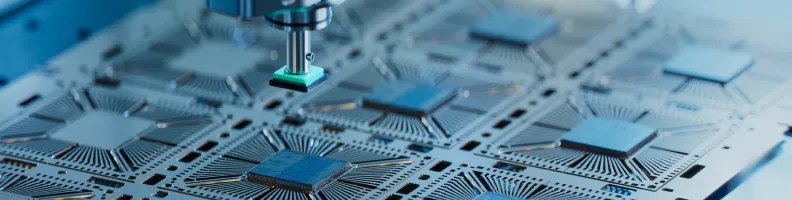

Smart factories are the heart of Industry 4.0. They combine sensors, cloud computing, and AI-driven insights to create a highly responsive production environment. Here’s what sets them apart:

-

Predictive Maintenance: Sensors track machinery in real time, alerting teams to potential issues before they disrupt production.

-

Enhanced Productivity: AI helps optimize workflows, allocate resources efficiently, and reduce downtime.

-

Flexible Manufacturing: Smart factories can switch between products or configurations quickly, meeting changing market demands.

-

Data-Driven Decisions: Insights from IoT devices help managers and operators make informed, strategic choices.

These advancements don’t just improve output—they can significantly reduce waste and energy consumption, aligning manufacturing with sustainability goals.

Benefits Beyond the Factory Floor

The impact of smart factories extends far beyond production lines. Companies adopting Industry 4.0 principles enjoy benefits such as:

-

Improved Supply Chain Management: Real-time data allows for smarter inventory management and better coordination with suppliers.

-

Higher Product Quality: Automated inspections and AI monitoring help detect defects early, reducing errors and recalls.

-

Cost Efficiency: Automation and predictive analytics help cut operational costs while maintaining high performance.

-

Employee Empowerment: Rather than replacing workers, smart systems often augment human roles, allowing teams to focus on creative problem-solving and oversight.

Challenges and Considerations

While the promise of Industry 4.0 is exciting, it comes with challenges. Implementing smart factories requires significant investment in technology and staff training. Cybersecurity is another major concern, as connected systems are vulnerable to digital threats if not properly protected.

Additionally, organizations must manage the cultural shift of integrating AI and automation into traditionally human-driven roles. Transparency, communication, and ongoing education are essential to make the transition smooth.

The Global Shift

Countries around the world are investing heavily in Industry 4.0 technologies. From Germany’s Industrie 4.0 initiative to smart manufacturing hubs in the U.S., China, and Japan, governments and businesses alike recognize that the future of competitiveness depends on digital transformation.

The adoption of smart factories is also influencing global supply chains, making them more resilient, adaptive, and capable of responding to market disruptions.

A Smarter Future

Smart factories and Industry 4.0 are more than technological trends—they represent a fundamental shift in how goods are made. By combining automation, data, and human expertise, these factories promise greater efficiency, sustainability, and adaptability.

As more companies embrace the smart factory revolution, the manufacturing landscape of tomorrow will be faster, smarter, and more connected than ever before. In the world of production, the future is here—and it’s intelligent.